Spot Welding

Welding is such an essential part of the metal fabrication business. It is this process that is responsible for joining two or more metallic parts at some stage in the metal fabrication process. For this reason, the process has to be carried out in a very careful and sound way.

If the process is not carried out in a careful way then it might lead to some dire consequences later on. This is one procedure that has to be carried out by professionals who know exactly what they need to do and exactly in which way. The reason why it is essential to do this is because of the recent cases where metallic structures intended for various purposes collapsed due to poor welding. This among other quality reasons are some of the things that make it so essential to carry out the process of welding in a very careful way with the view achieving the best results.

The first step to carrying out the process of welding in the right way is by looking for the right machines for this process. This is very key in this process as the right machines will guarantee you a smooth process all through this process. Other than that, the right machines for this process will also ensure the quality of this process. However, if you are stranger to this business you might fail to tell what the right machines are and what is not. In fact, you might find yourself paying your money for the wrong machines which is something you need to avoid at any given cost.

The best way to finding the right machines for this process is by looking for a reputable store around you. For instance, if you are a resident of Indiana you can look for Contract Manufacturing Specialists of Indiana for the best machines for this process. Other than the machines, it is important to note that there are so many types of welding that work differently. Before you land on any welding process you need to look for the best process that you are certain will deliver the best results for you.

To do this, you need to look for the metals that you are working with before determining the right method. There various types of welding used for various purposes. However, it is important to note that these methods do not work in the same way, they are distinct from one another.

One of the welding methods that we are going to look at today is spot welding. We need to look at what this method is and see where it can be best utilized. We also need to look at why the welding process is very different from the other.

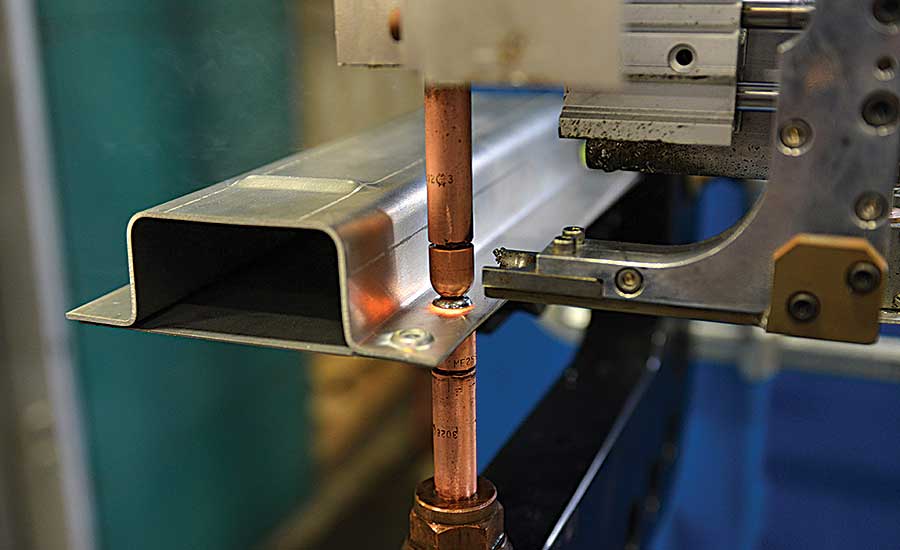

Spot welding

The perfect definition for Spot Welding is a type of electric resistance welding which is used in welding various sheet metals products. The goal of this type of welding just like any other type of welding is to completely join two or more types of sheet metal.

Unlike the other types of welding, this type of welding is carried out at specific points which are circular points. This type of welding is very common in the automotive industry. It is the type of welding that is used in creating the actual body of the car by welding various materials together.

Other than in the manufacture of motor vehicles, the type of welding is also used in welding furniture as well as other types of metals as well as electronics. The method basically works through a process known as conductive heating created by an electrical current.

Appropriate materials for spot welding

In the beginning, we did mention that spot welding works on certain materials while it does not work others. There are specific materials that can work well with Spot Welding while others might not. For instance, this process is very ideal for a sheet of metals as well as wire mesh. However, steel is mainly used for this process because of its low thermal conductivity as well as its high electrical resistance. However, not just all types of steel are the best for this process but a few, for instance, low carbon steel is the best for this process.

High carbon steel might not be the right metal for this process because of a number of factors. For instance, high carbon steel has the tendency of becoming more at the welds as well as being prone to fractures and cracking. On the other side, stainless steel, nickel alloys, titanium all work perfectly with this kind of welding. It is also important for you to know that spot welding can also be challenging on other metals like aluminum. The main reason for this is because aluminum and other few metals require a high level of electric currents to create welds.

Other than aluminum, galvanized steel also requires some level of higher electric currents to form welds using this technique. One of the most important things you need to know about this process is that it comes with so many requirements. For this reason, it is essential for you to know that this process comes with so many requirements among other things.

For this reason, it is essential for you to look for the best expert for this process who has the best understanding of this process. You need someone who will tell you what the right materials for this process are as well as carry out this process in the best way possible. Spot Welding comes with so many benefits compared to the other types of welding. Let us look at some of the benefits a person stands to get from spot welding.

More reliable results

Anytime you carry out any welding process you hope that you will end up with the best results. However, this is always not the case in many cases as you may fail to get the results due to many reasons. One of the reasons that might prevent you from getting the best results is the type of welding method you use to carry out the welding process. There are some types of welding that might not get you the results that you so much need for whatever material you are trying to weld. This is why you need to be very careful with the method you choose to use for this process.

If for anything you need a method that will deliver the best results to you. This is why you need to use Spot welding. Unlike the other types of welding, spot welding delivers the best and most reliable results. All you have to do as we said earlier on is to get a top and competent person to help you with this process. With such a person helping you with the process you will be able to get the best and high-quality results that you need out of the same process.

Long-lasting welds

This is also another reason why you need to use Spot welding in your motor vehicle welding business. As a person who is trying to come up with long-lasting welds that will satisfy your clients this the right method that you need to employ. With the method, you will be able to come up with long-lasting welds so long as this process is carried out in the right way.

It is a quick process

One of the other benefits of Spot Welding is that it is a quick process. This is not one of those processes where you will have to spend so much time trying to carry out the welding process. Spot Welding is a very smooth process that is also very fast to carry. It is very much possible to carry out the process and complete it within the shortest period of time possible.

Spot Welding is one of the best ways you can use to carry out the welding process. The factors listed above are some of the factors that you need to know about the same process as well as some benefits of the same.

There are so many things that make us be the best contract manufacturing company in the region. The top among them all is the kind of experts that we employ. We have a team of highly talented experts that will work on your project.

Our core offerings and services at Contract Manufacturing Specialists of Indiana includes, but is not limited to, the following below:

We service multiple cities throughout the state of Indiana. We provide all the services listed above, and much more in every city throughout Indiana.

If you don’t see your city listed or a specific service listed, don’t worry. All you have to do is contact us by either giving us a call or filling out our online contact form. Then we’ll discover what are some of the top solutions for you, your business, and executing a solid solution.