Small Batch CNC Machining

The metal fabrication business is booming now as it has never done before. The metal parts are used in so many places for so many reasons. From the production of motor vehicle parts to plane parts among other things metals are on high demand due to the rapid progress that is going in the current world.

Steel for instance is used in so many areas to carry production procedures in so many areas. For instance, it would not have been possible to have some of these buildings were it not because of steel. Steel has contributed so much to the construction of many buildings and steel does so up to now.

With the help of steel, it is now possible to come up with very complicated structures thanks to the capabilities of steel which come with immense features. Steel is just one of the many metals that are used in the metal fabrication process. The fabrication business is one big industry that continues to grow as days move. For those people who do not know, the process of metal fabrication is very detailed touching on so many things. If you are not privy to this process then you might not be able to tell what this process is exactly.

There are so many ways of carrying out the process of metal fabrication in many areas. This process depends on so many things with the most important of them being a success at the end of the process. For this reason, there are people who carry out this process in many different ways depending on the nature of the metals being fabricated.

One of the ways of carrying out this process is small-batch fabrication production which is very famous in some areas. The process of small batch production comes with its own importance as well as disadvantages as well. Nonetheless, there are so many things that warrant the need to engage in small-batch fabrication production. One of them is when someone is getting into the metal fabrication business and does not have the capacity to carry out bigger operations.

It is a proven fact that carrying out small batch production is less costly compared to the other types of fabrication. This is why this idea is always the best option for many people who do not have the capacity to carry out some of these big metal fabrication procedures. Other than this, small-batch also comes in as a good option in an event where there is a need to carry out proper marketing. The progress in any business is always dependent on so many things among them how you market your products.

Without the right form of marketing, you will never be able to sell your products as you may wish. One thing that should never be lost on you is that the rapid growth in the metal fabrication business means there is so much competition. This means if you are not doing something in the right way then we have someone else who is doing the right thing and more likely to take over your clients. For this reason, marketing is very integral in this business and something that you need to pay so much attention to. It is proven that it is easy to carry out the process of marketing in small batch production compared to the other types of production.

Small batch production

When people hear about small batch production they tend to wonder what this process is all about. Some of them think maybe this is small production in metal fabrication but that is not the case. The term small production cannot be used in such a context because of many reasons. There are very many reasons but we cannot look at all of them at once or for now. One of the reasons why small batch production is not referred to as small production is because the word small is very small and applies to different businesses differently.

For instance, what might be small to a big company might actually exceed the maximum production of a small business. This why small metal fabrication is not used in this context. Small batch production on the other hand is a very precise word that is used in the production business. Small batch production refers to the production of fewer than 500 parts. In the metal fabrication business, the word small batch production refers to the production of fewer than 500 parts. There are so many ways of carrying out this process especially in the metal fabrication business.

As a person who is just getting into the business, it is ideal for you to try out small-batch manufacturing or fabrication because of the benefits that this process brings. For instance, there is very little risk involved when it comes to small production. This method only allows you to produce a small number of parts that you can easily sell. This means you can easily sell these parts to clients. Other than that, small-batch production also offers you some sort of flexibility that you may not find with the other types of production.

You can easily switch from the production of some parts to the others within the shortest period of time. There will be no hassles involved like it is with the large-scale production like it is the case with the other types of production in other metal fabrication procedures. The cost of starting such as business too is not that much as is it the case with others. All you need are just some few machines together with some few people to handle these machines for you.

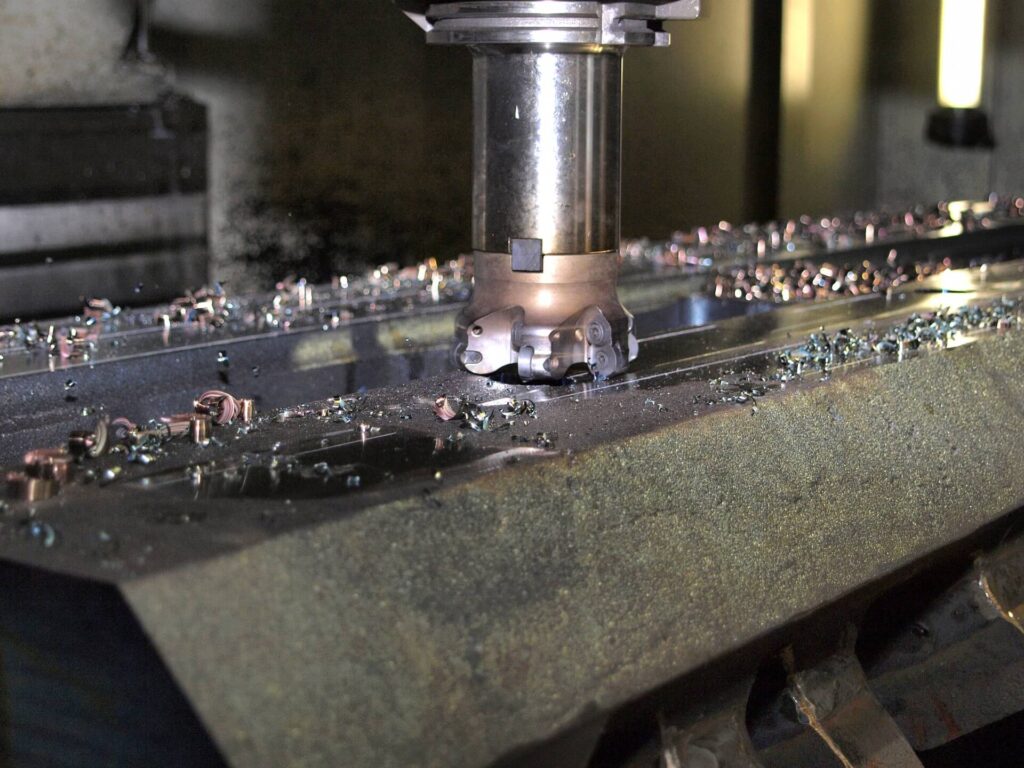

CNC machines in small batch production

The use of CNC machines is not a new thing in the metal fabrication business. These machines are used extensively in this business and continue to be used by more people who join this business. CNC machines come with so many benefits among them a speedy production.

If you are in metal fabrication business you might be wondering is it really necessary to try out Small Batch CNC Machining. Well, this is quite an idea in the metal fabrication business due to the benefits of this process.

CNC machines are known to come with so many benefits among them accuracy and speedy operations. This is such a catch in the sense that when carrying out such operations. One of the things you need to give priority to is the production of quality parts and products.

To produce these quality parts, you need to make use of the right machines to make this possible. This is why you need to try out CNC machines. These machines are known to produce quality parts compared to the use of manpower during the same process.

Other than that, there is the aspect of speed which is very important. As someone in the metal fabrication business you need to make sure that you carry out your operations within the shortest period of time. However, this is not an easy thing to achieve given the requirements needed to make this possible.

To work on speed, you need to make sure so many things go to plan as it is required. This might not be possible with manpower who are somehow unreliable to some extent. Machines on the other hand come with some sort of efficiency that people cannot offer you.

For this reason, of you are focused on working on your small batch production and considering making any serious progress you need to consider these machines. With their help, you will be able to work on your projects and deliver them on time. All you need to do is rush to Contract Manufacturing Specialists of Indiana for the best small-batch CNC machines.

Small Batch CNC Machining is the way to go if you are looking to make any serious progress in the metal fabrication business. With the help of these machines, you will be able to produce quality on time.

There are so many things that make us be the best contract manufacturing company in the region. The top among them all is the kind of experts that we employ. We have a team of highly talented experts that will work on your project.

Our core offerings and services at Contract Manufacturing Specialists of Indiana includes, but is not limited to, the following below:

We service multiple cities throughout the state of Indiana. We provide all the services listed above, and much more in every city throughout Indiana.

If you don’t see your city listed or a specific service listed, don’t worry. All you have to do is contact us by either giving us a call or filling out our online contact form. Then we’ll discover what are some of the top solutions for you, your business, and executing a solid solution.