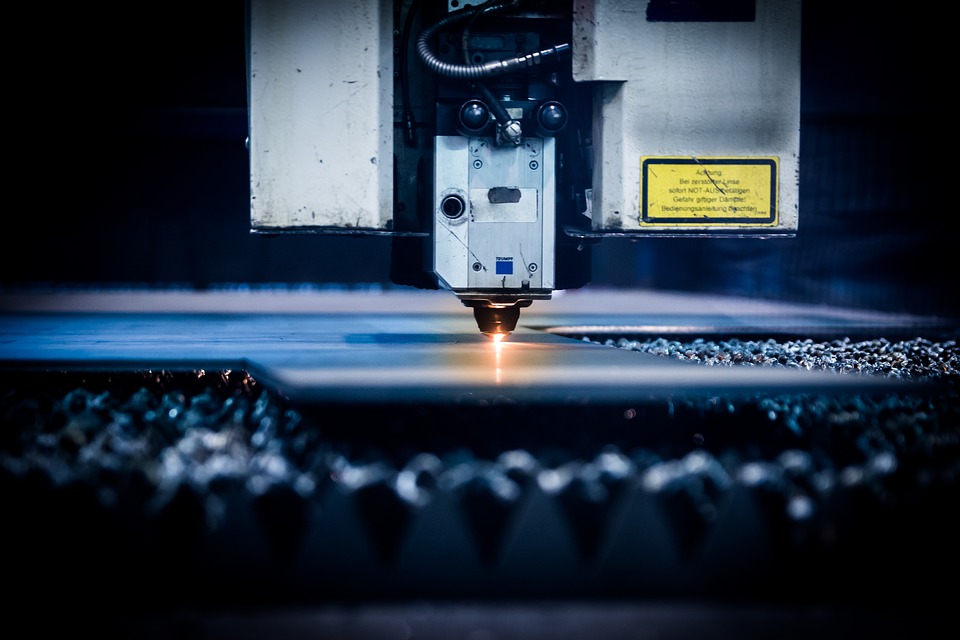

Laser Cutting

Laser cutting is a technique that is used to cut and profile plates or sheets of metal. It is appropriate for fabricating small or large batches of plate metals of just one-off contracts. This system is controlled electronically using the renowned CNC controlled technology. Each task is programmed specifically to make sure there is an efficient operation with minimum wastage. You will be guaranteed with a high level of accuracy minus or plus 0.2mm.

The CNC controlled laser cutting technique offers a highly precise way of profiling several materials. The most common ones include aluminum, stainless steel, mild steel, and brass. The most advanced machines can handle sheet and plate materials that are 1.5m wide, 3m long, and 20mm thick. They can profile sheet metals of these dimensions cleanly and rapidly. The machine works at relatively low temperatures to minimize heat distortion and produce excellent finished results. One of the best companies to work on your laser cutting process is Contract Manufacturing Specialists of Indiana. Most of the cutting services provide CAD, press braking, flatbed and tube box section, laser cutting, and 2D laser cutting.

Laser cutting typically measures dimensions of the 2D components, scans sample parts, and lastly delivers precise electronic drawing that is ready for manufacture and future references. You can also use laser scanning for high-quality inspection of the 2D components. When choosing a laser cutting professional, it is good to go for the one that offers all operations inhouse. It is the only way that you will be able to accelerate the process of delivery. Such a brand should be able to deal with the initial design and handle any alterations to the design and all the other components.

Flatbed laser profiling makes good use of the laser cutting machines that are capable of handling large plates and sheets of stainless steel, mild steel, brass, and aluminum. The size of these sheet metals can be up to 3,000mm long, the thickness of 20mm, and 1500mm wide. You can find such services from Contract Manufacturing Specialists of Indiana.

Laser cutting works by using computers to direct the output of the high-power laser. The material will then burn, melt, or vaporize away. The process is not as complicated as you could be thinking.

Whether you are creating heat exchanges, custom light fixtures, or decorative architectural pieces, a high level of precision and accuracy is key in customizable sheet metal fabrication. It is the only way that you will be able to record quality results. A laser cutting system is a very important equipment for sheet metal job shops that specialize in meticulous jobs on a variety of metals and thicknesses. If implemented in the right manner, laser cutting services will increase the accuracy, quality, and speed of the results. In addition to these advantages, using high-end technology will amplify the specialization and the diversity of the metal pieces that you can create. Here are some of the top advantages of laser cutting in Indiana.

Versatility

From stainless steel to aluminum, titanium to wood, you require different techniques for cutting and forming on various materials. Laser caters that have the ability to handle a broad range of materials that have a diverse degree of thickness allow users to undertake different types of jobs. It increases the capabilities of the job shop and improves the overall profitability of the business. regardless of the type of sheet metal fabrication that you need, you have the capacity of generating professional results. Therefore, versatility is one of the key benefits of using laser cutting.

Increased Productivity

Laser cutting services provide speed and accuracy when producing customized metal parts. It allows amplified productivity and makes the shop more efficient. For instance, laser machines that have dual pallets give workers the capacity to multitask. It is done by using a laser on a single pallet while unloading and reloading parts and materials on the others. Laser cutting services that are equipped with the features that have the capacity of correcting mistakes before taking place will help to escalate the productivity of the job shop. Remember laser cutting keeps inaccuracies at the minimum and allows for the creation of more precise parts.

Quality Results

With meticulous precision and spot-on accuracy that advanced laser cutting services produce, your customers will be able to get high quality, intricate, and detailed results. The final product will be fitted more securely and if you are working on replacement pieces, the new materials will be highly compatible with the old ones. The capacity of being in full control of the laser cutting makes sure that you get consistent results. The enhanced pulsing techniques will also guarantee you smooth edges. When laser cutting services are used effectively, the error margin in the cuts is reduced significantly. This leads to finished merchandise that looks, fits, and functions in a better manner.

Safety Features

The top priority for laser cutting should be safe when using powerful lasers to work on sheet metal fabrication. Some of the safety measures for the laser include the fume blowers that take away fumes from the region where laser cutting is taking place, automatic lubrication systems, and safety lights and mats. The best manufacturing contractor will have all these things in place.

Advice Before Buying a Laser Cutting machine

The laser cutting machine utilizes laser lights to cut through a broad range of materials like acrylic, textiles, wood, metal, and many more. When it comes to cutting metallic materials, you can use a laser to work on a broad range of materials like aluminum, steel, and stainless steel. Contract Manufacturing Specialists of Indiana specializes in steel laser cutting.

Most people prefer to use laser cutting because it is very accurate and has a small heat affect zone. Additionally, the process yields excellent cut quality and has a very small kerf width. Here are some of the things that you need to put into consideration to be able to choose the right laser cutting machine. Some of them include;

-

Function

-

Bed Size

-

Optic Quality

-

Ease of Use

The first consideration is how you will be using the machine. Cutting machines can either be used for engraving or cutting. As we have stated above, you can use them on a broad range of materials. Since the materials come with different specifications, make sure you decide how you will be using this machine before heading to the store.

The bed size that the laser cutting machine has will determine the amount of work that the machine can handle. The bed size typically varies from A1 to A3 in which bigger size machines have the capacity of handling more work. Since the bed size is a permanent feature, you cannot change it in the future. The amount of work that you are planning to handle is what should inform your decision. For instance, if your intention is to handle large projects, make sure you are choosing a laser cutting machine that has a large bed size.

The quality of the optics is crucial as it determines the performance of the machine. Most unknowledgeable individuals believe that the wattage is the one that normally determines the efficiency of the machine but this is not true. When going to make a purchase, the amount of power that the machine consumes should not bother you. It is better to concentrate on optical quality. To establish the quality of the optics, let the seller demonstrate to you the working on the machine on different materials and in different settings.

In case you are a new buyer, there is a high possibility that you don’t know how to operate the laser machine. The best machine should always come with a manual that is easy to follow. Apart from demonstrating how to operate the machine, the manual should also show you how to undertake minor repairs.

There are so many tips on how to buy and take care of the laser cutting machine. The machine is designed to cut various machines but the main applications are steel. You should avoid using it to cut plastic materials as it produces the chlorine gas that is harmful when you breathe it. The best brand to help you work on your laser cutting project is Contract Manufacturing Specialists of Indiana.

There are so many things that make us be the best contract manufacturing company in the region. The top among them all is the kind of experts that we employ. We have a team of highly talented experts that will work on your project.

Our core offerings and services at Contract Manufacturing Specialists of Indiana includes, but is not limited to, the following below:

We service multiple cities throughout the state of Indiana. We provide all the services listed above, and much more in every city throughout Indiana.

If you don’t see your city listed or a specific service listed, don’t worry. All you have to do is contact us by either giving us a call or filling out our online contact form. Then we’ll discover what are some of the top solutions for you, your business, and executing a solid solution.